Mention cameras in a business setting and everyone thinks about surveillance and security. In a sense, they’re right: surveillance and security are important benefits of industrial video monitoring systems.

But when it comes to industrial environments, video monitoring systems have benefits beyond security. At Opticom, we’ve been installing industrial video monitoring systems for 50 years now, so we know how industrial facilities can take full advantage of their CCTV systems.

Beyond surveillance and security, we hear these 8 major benefits of industrial video monitoring.

8 Unexpected Benefits of Industrial Video Monitoring

Each industrial application differs in the possible benefits—and scope of these benefits. For example, sawmills have different video monitoring KPIs from mines.

However, the benefits below generally apply across the board for industrial facilities:

1. Improve Operational Efficiency

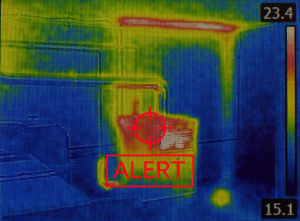

Video monitoring provides the situational awareness you need to improve processes, avoid costly downtimes, and plan your predictive maintenance. Overall, this means a boost in your operational efficiency.

By watching your processes in real time—or recording and analyzing them at a later time—you can spot opportunities for improvement. Moreover, you can spot potentially faulty equipment and plan its maintenance before it brings your production to a halt.

2. Safety Compliance and Accident Prevention

In industrial environments, there is nothing more important than the safety of your workers, your facility, and the surrounding area. Video monitoring systems help with all of these.

By monitoring your operations constantly, you can see which safety protocols are ignored or improperly implemented, and you can address these situations before they lead to tragic incidents. Moreover, if you are in a highly regulated industry, you can use the video feeds to prove your safety compliance.

3. Quality Assurance

Consistent product quality is one of the highest priorities in manufacturing plants. The tiniest change in process, equipment, or supplies can wreak havoc on product quality. To make matters worse, this change in quality may not be observable with the naked eye. Or if the quality issue is obvious, the underlying cause may not be.

Video feeds can help pinpoint quality issues and causes. Monitoring your manufacturing processes can alert you to quality discrepancies before you’ve produced entire batches. The sooner you catch the issue, the easier it will be to resolve and the more costs you save.

4. Remote Equipment and Process Inspection

Many Opticom clients operate more than one facility—some of which are far away from one another. This makes inspections time-consuming and cumbersome, especially since the inspectors have to travel long distances between facilities.

With video monitoring, you can conduct inspections anytime without interrupting operations. Inspectors can watch the live feed or the recording, zoom in and out as they need, and draw their conclusions and recommendations without traveling a single mile.

5. Regulation Compliance

Regulation compliance is one of those murky bureaucratic activities that most plant managers dread. However, the fines that you can get when you’re not compliant are even more dreaded.

If any incident takes place in your facility, your compliance will be under scrutiny for months. Worse yet, compliance is very hard to prove if you don’t have a video record of all your operations—especially those from the day of the incident.

Video monitoring can save the day by providing the proof you need to demonstrate your compliance. You can avoid hefty fines and costly shutdowns just by providing the inspectors with video feeds of your operations.

6. Environmental Compliance and Sustainability

In the upcoming years, every industry will have to deal with harsher environmental laws and regulations. For industrial facilities, emissions and waste are the top two sensitive areas.

Video monitoring can help you prove your compliance in both those areas effortlessly. And similar to operational improvements, reviewing video feeds can illuminate opportunities for improvement to work toward sustainability goals.

7. Remote Management and Supervision Made Easy

“When in doubt, zoom out” is a saying that refers to life or business decisions. In industrial settings—with video monitoring—it can be applied quite literally.

Monitoring your operations remotely isn’t just a way to cut costs—a single operator can monitor several processes at once. It’s also a way to spot glitches, process flaws, and worker efficiency much more easily. Video monitoring gives you a vantage point, a bird’s-eye-view, that helps you pinpoint mistakes and processes that can be improved upon at a glance.

8. Peace of Mind

Industrial environments are deemed harsh for several reasons. One of them is the fact that you know something can go wrong at any time and you can’t be in 1,000 places at once.

Video monitoring gives plant managers peace of mind, knowing that they can watch over seemingly 1,000 places at once. By monitoring the live feed, operators and facility managers save precious time and stay up to date with everything that happens anywhere in the facility.

Choose Your Industrial Monitoring System Wisely

Not all industrial video monitoring systems are built identically. To reap these benefits, you need a system that fits your unique requirements, without breaking the bank.

You don’t have to choose it alone. Our industrial video experts are just a click away.