When it comes to industrial video monitoring, uniformity is rarely the answer.

Facility managers know that no two areas of a plant, mine, or processing line are exactly alike. Some zones demand rugged durability or surgical cleanliness. Others call for a more standard camera like back offices and parking lots. A few need precautions to avoid explosions.

And yet, there’s a persistent myth that a “one-size-fits-all” camera solution is ideal. Choose a model, buy in bulk, and install everywhere. Problem solved, right?

Not exactly.

This is where hybrid video monitoring solutions come into play as a practical, strategic approach to visual oversight. It’s not about cobbling together a random collection of devices. It’s about intentional integration.

The right camera, in the right place, serving the right purpose.

Why Hybrid Isn’t a Compromise—It’s a Strategy

Let’s start by clarifying terms. A hybrid video monitoring solution doesn’t refer to a specific product or camera. It’s a system-level strategy that combines different types of cameras and monitoring technologies across a single facility.

The goal? To tailor video to the needs of each environment.

Think of it like a toolbox. You wouldn’t expect a wrench to do a screwdriver’s job. So why expect a basic IP bullet camera to operate effectively in a high-vibration environment or a corrosive washdown zone?

With hybrid systems, you can combine:

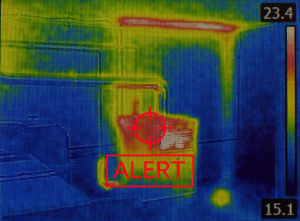

- Thermal cameras in areas where early detection of heat build-up is critical

- Stainless steel cameras in food-safe or pharmaceutical clean zones

- Industrial cameras in high-vibration or harsh environments

- Explosion-rated cameras in areas with combustion risk

Each camera serves a different purpose. Each is designed to excel under different stressors. The hybrid approach allows you to optimize your video monitoring system for performance, safety, and longevity.

This is why we always recommend that facilities work with an experienced partner when choosing their cameras. It’s a matter of saving on costs (at Opticom, we never recommend the expensive options unless you need them) and of enhancing your security and process video monitoring.

One Facility, Many Environments

Let’s think about a sawmill.

You’ve got exterior yards with exposure to dust, moisture, and temperature swings. Inside, machinery hums and rattles with constant vibration. Some areas are high-risk for combustible dust buildup. Others are tightly controlled operational zones that require real-time visibility into process details.

What camera can do all that? Honestly? None.

But a hybrid system can.

- Install thermal cameras to watch kiln zones or motors prone to overheating. (Bonus: Our thermal cameras are dual-sensor so they also provide a regular video feed.)

- Use durable industrial cameras in process areas with dust, vibration, heat, and other challenging factors.

- Install explosion-rated cameras where sawdust or gas accumulations create potential ignition zones.

- Use standard IP cameras in administrative offices or other low-risk, low-interference environments.

Each camera should be chosen with its location and use case in mind. That’s the essence of hybrid video monitoring solutions.

What About Integration for Hybrid Video Monitoring?

A common pushback to hybrid video monitoring solutions is the perceived complexity of managing multiple types of cameras and feeds. Different hardware, different interfaces, different standards. It sounds like a logistical nightmare.

That used to be true. Not anymore.

Today’s video management systems are built with interoperability in mind. Open-source standards paired with modern platforms can pull together all those feeds into a centralized dashboard.

You don’t need ten interfaces for ten camera types—you need one intelligent system that plays well together.

That said, integration is only as smooth as the planning behind it. This is why working with an experienced partner is critical—not just for installation, but also for planning and design.

Not all cameras “speak” to each other, so a skilled partner can recommend the ones that do.

Camera Selection Is a Technical Process

Too often, industrial camera systems are installed based on cost, availability, or guesswork. But the reality is that camera selection is a technical decision, not a procurement one.

Here’s what a qualified hybrid video monitoring systems partner will help you assess:

- Environmental Hazards: Will the cameras be exposed to heat, dust, moisture, vibration, or an explosive atmosphere?

- Regulatory Compliance: Does the area require NSF-certified stainless steel or explosion-rated electronics?

- Process Goals: Are you monitoring for safety, process efficiency, asset protection, or all of the above?

- Field of View/Lighting: Are we looking at a small zone or a wide area? In daylight or darkness? Will thermal or dual-sensor video be more appropriate?

For example, in a food processing facility, you may need stainless steel cameras in washdown zones to avoid corrosion and maintain hygiene compliance, but only need standard IP cameras in storage areas.

In a sawmill, you’ll want dual-sensor thermal cameras watching operations and for predictive maintenance, and you may want cameras with high temperature ranges for areas that get above 122ºF. With this approach, you’ve got a hybrid video monitoring solution with each camera doing what it does best.

Hybrid Video Monitoring Solutions Are Not Just a Trend

Hybrid video monitoring solutions aren’t a gimmick or a phase. They’re simply an acknowledgment of how complex industrial environments really are.

And they’re a challenge to the idea that one device can serve every need in a modern facility.

The smarter approach is to mix and match intentionally, guided by the demands of each space and the expertise of a partner that knows how to balance durability, visibility, and compliance.

Not sure how to mix and match? You don’t have to do it alone. Schedule a free consultation with our video monitoring experts.