When monitoring an industrial facility, it’s easy to think that any camera will do the job, as long as it captures footage. After all, most cameras are designed to capture video, right?

Just because a camera can record footage doesn’t mean it’s right for any environment. Particularly when it comes to video monitoring in industrial environments, where the stakes are higher than just ensuring a trespasser doesn’t wander into the break room.

Think about it this way: would you use the same food blender at home and in a food processing facility? You wouldn’t — because a food processing facility needs a bigger capacity, more strength, and increased durability.

Similarly, security cameras are great — when used for security. But when you start talking about monitoring processes, machinery, and environments where every detail matters, using security cameras is like using a hammer when you need a scalpel.

Security Cameras: Designed for Security, Not Performance in Harsh Environments

Security cameras are made with a singular goal in mind: to monitor and record for safety and security purposes. They’re fantastic at keeping an eye on entrances and exits and at monitoring areas like parking lots and back offices — where the environment is stable and the conditions aren’t pushing the limits of what the camera can handle.

However, when you move into harsher environments like sawmills, manufacturing floors, mines, or any area where machines are humming, engines are whirring, and your hygiene practices are closely regulated, security cameras quickly fall short.

These cameras are not built to withstand the physical demands and extremes that industrial environments throw at them. Sure, they can function, but only for a while — until they start failing.

Our customers have had security cameras installed in harsh environments, and they come to us when they’re tired of replacing the cameras every month (or more). We set up video monitoring with ruggedized cameras that can withstand direct hits.

This is why ruggedized cameras have a lower cost of ownership, even if the upfront investment is higher.

Security Cameras Aren’t a Fit for Industrial Facilities

It’s not just about the camera being able to see and record what’s happening in a facility. It’s about whether it can endure. Endure what, you ask?

Well, quite a few things:

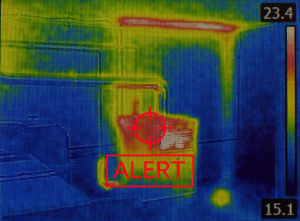

- Vibration: Machines in production areas don’t just stay still and calm. They rattle, shake, and move. A typical security camera isn’t built to handle constant vibration or frequent movements, especially in environments with machinery that operates at high speeds. The risk? Blurry footage or, even worse, a camera that stops working altogether when its sensitive electrical components experience vibration.

- Dust and Debris: Many industrial settings, particularly manufacturing facilities, sawmills, and mines, deal with dust, dirt, and debris. These airborne particles can accumulate on camera lenses, severely impacting image quality, and they can get inside camera housings and destroy critical components. Not to mention, the general wear and tear from harsh working conditions can cause cameras to break down faster than you can say “not covered under warranty.”

- Chemical Exposure: In certain industries, like those dealing with chemicals or harsh solvents, cameras might be exposed to all sorts of abrasive substances. Security cameras simply aren’t built with the resistance to these environments in mind. They might not survive the exposure, let alone function at optimal levels.

Why Industrial Cameras Are the Answer for Industrial Facilities

Industrial cameras don’t just look tough — they are tough. Unlike security cameras, they can withstand almost anything.

Not all industrial cameras are built the same either. Some are ideal for damp environments, while others can withstand the highest level of vibration especially when they are placed on a vibration-resistant mount.

Industrial cameras are engineered to handle the challenges of industrial settings. They are specifically designed to withstand extreme temperatures, vibrations, and exposure to dust, chemicals, and moisture. They keep on running so you don’t have to worry about constant maintenance or failures during critical moments.

Moreover, they are built for the long haul. They’re designed to endure the wear and tear that comes with being inside an industrial operation. Unlike security cameras that might need to be replaced frequently, rugged cameras offer superior durability and a longer lifespan, which means you won’t have to waste resources on constant replacements.

Think Video Monitoring Systems, Not Individual Cameras

At Opticom Tech, we pride ourselves on being our customers’ partners, not just their camera sellers. Because we know that no two environments are identical. We take the time to advise everyone not just on the cameras they need but on the entire system.

The beauty of the systematic approach is that you don’t have to choose between security and video monitoring. In fact, the best approach for many facilities is a mix of both.

Many facilities can use non-industrial cameras for entrances and exits while deploying rugged industrial cameras in the harsh, mission-critical environments that need real-time monitoring.

This hybrid approach ensures that you’re covered both for general security and for the specific needs of video monitoring in more demanding areas, all without spending a fortune on your monitoring system.

Not sure where to start building the right video monitoring system for your industrial facility? Get in touch with our experts.