IP monitors for industrial facilities get talked about very rarely—industrial video cameras get all the attention. In a way, it makes sense: cameras are the ones that endure the worst things in harsh environments.

On the other hand, no operations monitoring system is complete without the right monitors. Whether you need a monitor in the operator cab or in the plant office, IP monitors can provide the sturdiness and flexibility you need.

5 Reasons Why IP Monitors Are the Best Choice for Industrial Facilities

Monitors for industrial facilities generally don’t need the same level of ruggedness as cameras that might be on the production line. However, since they will most likely be exposed to some harsh conditions, have sensitive electronic components, and you don’t want to replace them every few months, it’s a good idea to avoid opting for off-the-shelf monitors.

Here’s why:

1. Industrial IP Monitors = Longevity and Sturdiness

Unlike their off-the-shelf counterparts, industrial IP monitors are fit for purpose. They are created specifically for video monitoring and are not computer monitors or TVs.

More importantly, they usually come with metal housings, like the Opticom LCDI-32IP-32 monitor. Even if you don’t use them in a harsh environment, protecting the IP monitor from the dust and humidity that are inherent to most industrial environments will extend its lifecycle.

Industrial-rated monitors aren’t just for extra-harsh environments. They are also ideal for heavy use. While your desktop monitor might be on for 8-9 hours a day, an IP monitor is often on 24/7/365 to display a continual video monitoring feed.

This means that its internal components have to withstand increasing temperature ranges. IP monitors are designed differently, with different circuits, a different layout (to allow easier cooling), and different components.

If you’ve tried off-the-shelf monitors in the past and had to replace them, give IP monitors a try.

2. You Don’t Need Additional Hardware

Regular desktop monitors can display CCTV feeds—however, in order to do so, they need a lot of additional hardware. IP monitors, on the other hand, don’t. They are a complete system in a single frame.

IP monitors can be plugged right into the power over ethernet (POE) switch and thus access the cameras directly. That means the system doesn’t need:

- A computer

- A server (IP monitors have built-in servers)

- All the various cables that you would otherwise need to connect all these elements

On industrial sites, especially in operator cabs, this is a game-changer. Fewer components and cables mean fewer accident risks, more space inside the cabs and easier maintenance.

3. IP Monitors Are Built for CCTV

IP monitors are built to be used for one thing: video monitoring. When you look at an IP monitor, it might just look like a regular computer screen. But what very few people know is that IP monitors also process the video, unlike a TV that has an ethernet port to allow internet access.

With IP monitors, you don’t need to connect your cameras to the internet, unless you want to. An IP monitor also avoids burn-in, like how when you watch a TV station for a while and there’s a faint image of the logo left in the corner.

4. Ideal Fit for Industrial Environments and Operator Flexibility

Most industrial sites are harsh on electronic equipment. Industrial-grade IP monitors, however, can withstand dust, debris, temperature changes, and moisture. They also help work around space constraints—they can even be installed on the floor, which no regular monitor could withstand.

Moreover, your operators can enjoy real flexibility. They can view only the cameras they need to at any given time; they’re not bound to view all the cameras at once or just one at a time. They can be configured to any layout you need—1×1, 2×2, 3×3, 4×4, and so on.

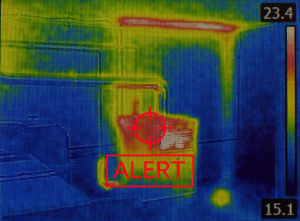

For example, if some areas of your site aren’t operational, there’s no point in cluttering operators’ monitors with feeds from those areas. They can also zoom in and zoom out as they see fit—a useful feature when the operator spots an equipment malfunction or a potentially hazardous event.

5. Support for Various Cameras, Interfaces, and More

Opticom IP monitors support a variety of cameras and configurations:

- Third-party IP cameras that meet ONVIF protocols

- Full support for dual stream—substream and mainstream (full-screen mode provides mainstream, while multi-view provides substream to save bandwidth)

- You can make any modifications to your stream in a web engine thanks to the support web interface

Choose the Right IP Monitors for Your Industrial Applications

There are no two identical industrial applications. Depending on your industry, the particularities of your environment, the needs of your operators, and your operating regulations, you will need different monitoring systems and, consequently, different IP monitors.

At Opticom, we have spent over 50 years helping facility electrical managers choose the right monitoring systems that match their needs and their budget. There’s no point in saving a few dollars in the short term to get a monitor that will need to be replaced every couple of months.

Need expert help setting up a complete industrial video monitoring system? Or maybe you just need some IP monitors. Either way, our consultants are just a click away.