Mining is one of the most highly regulated industries—and for good reason. While the worldwide demand for high-value minerals is constantly increasing, it is only natural that mine operators are looking for better ways to extract and process raw materials.

Today, with advances in mining equipment, some mines can run essentially autonomously. Advanced equipment can perform many of the key mining operations in certain instances, reducing workforce and human safety concerns.

When a mine is operating with high autonomy via technology, video monitoring is vital. While the process mostly runs on its own, any problems that do arise need to be identified early and fixed immediately.

Let’s take a look at some of the most common challenges mine operators face and find out how video monitoring can help.

Ensuring Visibility in Poorly Lit and Dusty Areas

We usually think of mines as dark tunnels underground. While not all mines are underground or made of tunnels, poor visibility is a characteristic they do share.

For automated mining operations, that means video cameras need to be able to record footage through hard-to-see conditions and also need to stand up to the dust and debris of the harsh mining environment. With Opticom’s cameras, sensitive video components are surrounded by a virtually indestructible titanium alloy housing, protecting them from dust, moisture, vibration and extreme temperatures. Mine video monitoring requires robust cameras that don’t need replaced when exposed to a little dust.

Better Machine Operation and Management through Video Monitoring

Industrial video monitoring systems allow operators to monitor mine operations from afar to identify and alert on any potential issues. This saves workforce time, money, and human safety.

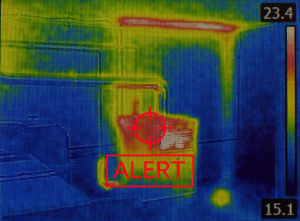

With autonomous mining, one issue that commonly arises is equipment overheating. This is where thermal video monitoring comes into play. Thermal video monitoring can help identify if machinery is overheating, or on the other end, cold and not running as expected. These systems can help avoid serious accidents, explosions, and equipment failures.

Thermal cameras can monitor equipment temperature, and operators can watch to make sure temperatures stay in expected ranges. If overheating starts to occur, the equipment can be shut down, repaired, and brought back online—instead of letting overheating lead to equipment failure or even an explosion.

Autonomous mining equipment is expensive, and keeping it from overheating by monitoring its thermal status can extend the use life and save money. Any issue with mining equipment costs time and money, which is why operators choose thermal video monitoring and sending footage via IP, Wifi, etc. to remote monitoring stations.

Video Monitoring Solutions for the Mining Industry by Opticom

At Opticom, we specialize in creating ruggedized video equipment for the mining industry. All our cameras and accessories are designed to withstand the harshest environments and to help you ensure the uptime and productivity of your mining operations.

Some of our bestselling cameras for the mining industry are:

- CC02 Rugged Industrial Analog Camera

- CC04-IP2MV Rugged Industrial High Definition IP Networking Camera

- CC04-IP3MV Rugged Industrial High Definition IP Networking Camera

- CC06-HB36F AISI SS316 Analog Stainless Steel Camera

Not sure if they are the right choice for your mining site? We’re happy to advise you on the best solutions for video monitoring and thermal imaging. Get in touch.