Can you imagine a sawmill without a video monitoring system these days? We can’t! But there’s one thing that comes up in every conversation we have with sawmill electrical supervisors: How do you demonstrate and maximize the ROI of sawmill video monitoring?

It’s a great question because it goes far beyond security and basic operations monitoring. The ROI of sawmill video monitoring can be incredibly high—provided you use the right solutions. But that goes for any piece of equipment in industrial environments, doesn’t it?

Let’s take a quick look at why sawmill video monitoring systems are a must-have and how you can maximize their ROI.

The ROI of Sawmill Video Monitoring: What to Expect

It’s hard to put numbers to the ROI of sawmill video monitoring precisely because it touches on so many areas. It can revolutionize operations, enhance efficiency, maintain safety, and ultimately contribute to a healthier bottom line. What that means is numbers vary from sawmill to sawmill.

However, there are a few key areas where all our clients tell us they’ve seen ROI from Opticom sawmill video monitoring systems.

1. Enhanced Operational Efficiency

Video monitoring systems offer real-time insights into the production process. You can monitor your equipment, machinery, workflow, and more.

Your sawmill supervisors can review the footage or watch the live stream to identify bottlenecks, inefficiencies, and potential downtime issues. By identifying them quickly, you can intervene immediately, reduce downtime and optimize production. The result? The ROI of sawmill video monitoring increases each time an incident is prevented or stopped early.

Even if an Opticom camera gets hit by a board, it can still keep running to help in incident resolution.

2. Predictive Maintenance

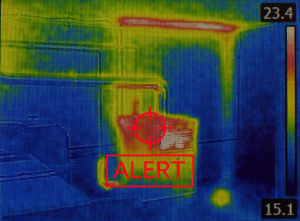

Through video monitoring, you can watch for signs of potential equipment failures before they occur. A remote operator can analyze the machines’ behavior and spot subtle changes or anomalies—line backups, logs coming down the line sideways, unexpected slowdowns, etc.

When that happens, you can act immediately and enable timely maintenance. Preventive maintenance and preventive measures significantly reduce repair costs, prolong equipment lifespan, and minimize unplanned downtime, all of which contribute to higher ROI.

3. Worker Safety and Productivity

Sawmills are harsh environments, prone to accidents and incidents. The main concern of sawmill supervisors is, understandably, the safety of their workers. Sawmill video monitoring inherently improves safety by allowing operators to watch the line from the safety of a cab.

Plus, with video monitoring, supervisors can analyze worker behavior and identify areas for improvement, implement targeted training programs, and make sure that safety protocols are followed.

Reduced accidents and improved productivity directly translate to cost savings and increased ROI.

4. Quality Control

High-quality timber products are the hallmark of a successful sawmill. Industrial video monitoring allows supervisors to closely monitor the production process, ensuring that products meet desired quality standards.

By detecting defects or inconsistencies early, corrective actions can be taken promptly, minimizing waste and ensuring customer satisfaction. And, of course, better products and happy customers translate to better ROI.

How to Boost the ROI of Sawmill Video Monitoring

All the ROI drivers above can be cranked up if you use the right video monitoring solution—one built and tested specifically for sawmills.

You wouldn’t use food processing equipment in a sawmill, would you?

The same goes for cameras. If specifically designed for industrial applications, they can withstand nearly anything, even being hit by a log.

Quality rugged cameras are made to last, even in a high-vibration, debris-filled environment. For you, this means a lower cost of ownership and a better long-term ROI.

You could opt for off-the-shelf cameras and get away with a little bit lower initial investment. But cameras are sensitive pieces of equipment; they don’t fare well in harsh environments if they weren’t specifically built for that purpose.

So you’ll end up replacing them every few weeks or months. When you replace your sawmill cameras that often, the costs start racking up: You pay for the cameras and the installation and, more importantly, you incur downtime. This chips away at your ROI and your initial “savings” on your investment ends up being money down the drain.

Lastly, don’t forget that there is more to a sawmill video monitoring system than cameras. Vibration mounts, for instance, are often overlooked but very important. A vibration mount is what saved our client’s camera from destruction when a log hit it. Since they are designed to absorb vibrations and shocks, they protect the most important (and expensive!) part of your system: the camera.

Industrial rugged cameras like Opticom’s CC02 and CC04 are the cornerstone of high-ROI sawmill video monitoring. Choosing the right equipment ensures that your investment is protected for years to come and that you won’t experience interruptions in your video monitoring.

Not sure how to choose the right video monitoring system for your sawmill? We’re just an email or a phone call away!

At Opticom, we have been helping sawmill electrical supervisors choose the best monitoring systems for 50 years. We don’t believe in one-size-fits-all solutions, so we always provide personalized consultations and advice. Let’s maximize the ROI of your sawmill’s video monitoring system together.