When we say “video monitoring,” a lot of people think we just mean surveillance and security. But as we continue to say, video monitoring and industrial cameras aren’t just for surveillance.

Strategic companies increase their video monitoring ROI by using their camera system for preventive maintenance. Unplanned downtime, emergency repairs, and rushed part replacements aren’t just frustrating; they bleed money from a facility’s budget.

Preventive maintenance is the smarter play, but here’s the problem: traditional maintenance relies on scheduled inspections, manual checks, and the occasional gut feeling from the most experienced technician on the floor. It works — until it doesn’t.

This is where video monitoring comes in. Think of it as your all-seeing maintenance assistant, keeping an eye on critical equipment and facility conditions 24/7.

With the right setup, video monitoring helps facility and electrical managers detect potential issues early, reducing costly shutdowns and extending the lifespan of equipment.

Let’s look at how video monitoring gives a preventive maintenance strategy an ROI boost.

1. Catch Problems Before They Escalate

If a bearing starts to wear down or an electrical panel overheats, would you rather:

- Wait for the issue to cause a catastrophic failure?

- Spot it early and schedule maintenance before it turns into a costly disaster?

Video monitoring gives you the ability to choose option B every time. Cameras placed in key areas can help you visually inspect equipment without shutting anything down. You can check for visible wear, leaks, corrosion, or blockages from a safe distance, even in hazardous environments.

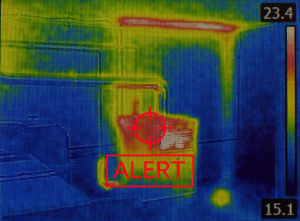

Thermal cameras can also reveal overheating components before they fail — giving maintenance teams the upper hand.

2. Reduce Downtime and Keep Operations Running

Nothing kills productivity (or profits) faster than unexpected downtime. A single failure in a critical system can bring an entire production line to a halt, costing hundreds of thousands — or even millions — in lost revenue.

Video monitoring helps by allowing real-time inspections and reducing the need for unnecessary shutdowns. Instead of shutting down a line for a routine check, maintenance teams can review video footage and confirm whether a full inspection is necessary.

Better yet, when you do need to shut down equipment for maintenance, video monitoring helps maintenance teams plan it efficiently. If a component is showing early signs of wear, maintenance can be scheduled during planned downtime instead of dealing with an emergency failure.

3. Extend Equipment Life and Reduce Replacement Costs

Industrial equipment isn’t cheap, and replacing major components before their time is a budget killer. Poor maintenance — either doing too much or not enough — can dramatically shorten the lifespan of machinery.

With video monitoring, you get an ongoing, non-intrusive way to assess wear and tear. Instead of relying solely on fixed maintenance schedules, you can base repairs and part replacements on actual wear-and-tear conditions.

If a machine is performing well, there’s no need to take it apart just because it’s “that time of year.” On the other hand, if a component shows signs of deterioration, you can act before it leads to costly damage, even if its scheduled maintenance is months away.

4. Improve Safety for Maintenance Teams

Maintenance work in industrial environments often means spending time up close to (or even inside of hazardous equipment. Without the right precautions, workers can be exposed to high voltages, extreme heat, or moving parts.

Video monitoring allows maintenance teams to conduct inspections remotely, reducing unnecessary exposure to dangerous conditions. Instead of climbing into tight spaces or dealing with high-risk environments, technicians can first review footage to assess the situation safely.

This not only reduces the risk of injury but also helps teams respond faster when real problems arise.

Plus, you can always use the footage to train new workers, which ensures that you limit the number of incidents and accidents in your facility.

5. Better Compliance and Documentation

For industries with strict regulations, maintenance documentation is non-negotiable. When an inspector asks for maintenance logs, you don’t want to scramble to piece together handwritten notes from three different clipboards.

Video monitoring provides a clear record of equipment conditions over time. If a component failed, you can review the footage to determine what happened and when. This kind of documentation is invaluable for audits, insurance claims, and compliance reporting.

It also helps prove that maintenance was performed when required. Instead of relying on written reports alone, video records provide undeniable proof that inspections took place.

6. Reduce Labor Costs While Increasing Efficiency

Most maintenance teams are stretched thin. There’s always more work than hands to do it, and sending technicians on unnecessary inspection rounds wastes valuable time.

Video monitoring allows teams to work smarter. Instead of conducting routine visual checks in person, they can monitor equipment remotely and focus only on areas that need attention. This means fewer wasted hours walking the floor and more time spent addressing real maintenance needs.

For facilities with large campuses or multiple locations, the cost savings here are massive. A central team can oversee multiple sites without sending personnel for unnecessary travel.

Wrapping Things Up: Preventive Maintenance Pays Off

Preventive maintenance has always been a cost-saver, but video monitoring takes it to the next level. By providing real-time visibility into equipment conditions, reducing downtime, and extending asset life, it delivers a measurable return on investment.

Not sure what type of video monitoring system can help you achieve all that? Don’t worry — you don’t have to make the hard choices alone.

At Opticom Tech, we help facilities build systems to save on upfront costs without compromising on quality. We’re here to advise you on the best way to build your video monitoring system. Schedule a call here.