Food processing facilities face relentless scrutiny when it comes to safety, hygiene, and regulatory compliance. From FDA mandates to USDA inspections, the industry operates under a microscope—and for good reason.

One recall, contamination event, or safety violation can not only trigger financial losses but also severely damage consumer trust and brand reputation.

While food safety plans often focus on equipment like mixers, conveyors, and packaging machinery, the technology monitoring all of it is just as critical. Cameras installed in food processing environments need to do much more than capture footage—they must actively contribute to maintaining a sanitary, compliant workspace.

That’s where AISI SS316 stainless steel cameras come into play. These industrial-grade cameras are designed specifically for harsh washdown environments and stringent hygiene standards required in food processing facilities.

Let’s see how they can help you with safety and compliance.

Monitoring Hygiene and Compliance in Food Processing Plants

The Food Safety Modernization Act (FSMA) has fundamentally shifted how food processing plants approach safety. Preventive controls, sanitation programs, and comprehensive documentation are now non-negotiable.

However, many facilities overlook the fact that every single surface in a food processing environment—including cameras—can become a contamination risk if not properly cleaned and maintained.

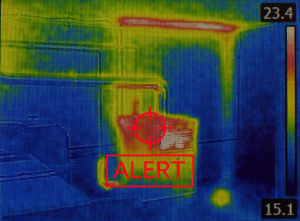

Camera systems are essential for monitoring operational hygiene, employee best practices, and product handling in real time. But if the cameras themselves can’t withstand the facility’s rigorous washdown process, they become a liability rather than an asset.

This is why food-grade stainless steel cameras are essential, not optional.

Compliance With Stainless Steel Cameras

The consequences of non-compliance in food processing are staggering. In 2024 alone, the FDA and USDA issued over 300 food recalls in the United States. Many of these incidents were triggered by contamination linked to poor sanitation, equipment failure, or improper handling—all factors video monitoring can help identify early.

Stainless steel cameras play a proactive role in supporting compliance in several ways:

- Continuous Monitoring: Cameras capture footage of sanitation and cleaning procedures, providing visual documentation to demonstrate compliance during audits.

- Prevention of Cross-contamination: By resisting bacterial buildup and enduring thorough washdowns, stainless steel cameras reduce the risk of harboring contaminants that could compromise food safety.

- Enhanced Traceability: In the event of a contamination incident, high-quality footage from hygienic cameras helps identify root causes quickly—whether it’s a lapse in cleaning protocol or improper handling by the staff.

Washdown Environments Demand Purpose-Built Cameras

One of the most demanding aspects of food processing is the washdown cycle. Floors, walls, equipment—everything is subjected to frequent, intensive cleaning using high-pressure hoses, sanitizers, and disinfectants.

Cameras are not exempt from this process.

Standard cameras—even those marketed as water-resistant—rarely hold up in this setting. Moisture intrusion, chemical damage, and corrosion shorten their lifespan dramatically, leading to blurred images, electrical faults, and recurring replacement costs.

Opticom’s stainless steel cameras, built from AISI 316 stainless steel, are specifically engineered to withstand:

- High-pressure washdowns

- Exposure to cleaning agents, including chlorine-based disinfectants

- Temperature swings between hot wash water and cold production floors

This durability doesn’t just preserve camera functionality, it also preserves compliance and traceability by ensuring reliable video footage 24/7, even in the harshest of conditions.

Why Visible Compliance Matters in Food Processing

Compliance isn’t just about ticking boxes for auditors. It’s about building a culture of accountability across every level of your operations. When employees know they are monitored, and that cameras are installed specifically to uphold safety and hygiene, behavior improves. As the saying goes, “What gets monitored gets managed.”

Stainless steel cameras send a clear message to staff, auditors, and customers alike: this facility prioritizes food safety at every level, including the equipment used to monitor it.

Find more details about how video monitoring improves compliance here.

Stainless Steel Cameras as an Investment in Reputation

Recalls, contamination incidents, and safety violations don’t just hurt the bottom line—they erode public trust. In an era where consumers demand transparency and traceability, food processors must actively demonstrate their commitment to safety.

Choosing hygienic, food-grade video monitoring equipment is part of that commitment. It shows that safety isn’t just a policy—it’s built into the very infrastructure of the facility.

Opticom’s stainless steel cameras are more than rugged hardware; they are a strategic investment in brand reputation.

What Makes AISI 316 Stainless Steel Ideal for Food Processing Cameras?

Not all stainless steel is created equal. AISI 316 stainless steel, the material used in Opticom’s food processing cameras, offers a unique combination of properties that directly address the challenges food facilities face:

- Corrosion Resistance: Processing environments involve constant exposure to moisture, cleaning chemicals, acids, and temperature fluctuations. AISI 316 stainless steel contains molybdenum, which enhances its resistance to pitting and crevice corrosion—both common issues in food plants.

- Durability in Washdown Processes: Food processing areas undergo aggressive washdowns, often involving high-pressure sprays and caustic cleaning agents. Cameras must endure these cleaning cycles without degrading or compromising image quality. AISI 316 steel holds up against these stresses, far outperforming standard aluminum or plastic camera housings.

- Compliance With Food Safety Standards: Equipment in contact with food zones must adhere to Hygienic Design Principles established by organizations like 3-A Sanitary Standards and EHEDG. While cameras are not direct-contact equipment, any surface exposed to food processing must still meet stringent cleanability standards. Stainless steel helps facilities align with these requirements.

Wrapping Things Up

For food processing facilities, compliance isn’t optional—and neither is choosing the right video monitoring equipment. Cameras that can’t withstand the facility’s cleaning processes, or that contribute to contamination risk themselves, have no place in a food-safe environment.

When food safety, compliance, and reputation are on the line, compromise isn’t an option. Choose cameras that meet the same high standards as the rest of your processing equipment—and make stainless steel the default, not the exception.

Explore Opticom’s full range of food-grade stainless steel cameras and discover how they help food processors stay compliant, safe, and audit-ready. And read more about how industrial-grade cameras support food processing operations.

Not sure whether they are the right cameras for your food processing plant? Get in touch with our experts and schedule a free consultation.