In March 2020, food and agriculture production was identified by the Department of Homeland Security as one of the 16 critical infrastructure sectors. This is a significant recognition, as it allowed food processing plants to continue their activity even during the pandemic. With the pandemic in our rearview mirror, this recognition shelters them from any future disruptions.

However, it also comes with more compliance and regulatory issues. While health and safety are the top concerns in the industry, production efficiency and business operations are not to be neglected either. With a more and more unstable geopolitical climate, a lot rests on the shoulders of food processing facilities.

Video monitoring can help take some of that burden off your shoulders. It can improve processes and compliance, along with streamlining processes. Here’s how:

5 Advantages of Video Monitoring in Food Processing Facilities

When you hear “video monitoring,” security is often the first thing that springs to mind. Granted, enhanced security is not a small feat, but video monitoring in food processing plants can help with a lot more.

1. Video Surveillance Can Assist with FDA Inspections

The Food Safety Modernization Act (FSMA) of 2011 greatly increased the FDA’s authority regarding food processing. To a great extent, the FSMA was enacted to combat foodborne illnesses.

As you already know, FDA inspections aren’t super easy to pass. Video surveillance can help you prove your point, especially through its physical security component: you can prove that your processing plant was not contaminated from the outside by showing footage of who had access inside.

Moreover, video monitoring can help you prove that the storage and use of toxic chemicals are thoroughly secured. When combined with access control systems, video surveillance can be your best ally during an FDA inspection.

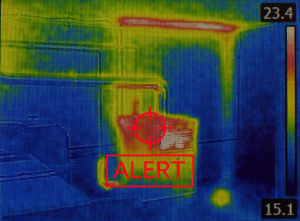

2. Identify Equipment Failure Quickly

When essential equipment is down, your entire plant can stop working. Depending on how long it takes to get to the root of the problem, you can lose hundreds of thousands of dollars because of activity disruptions.

Through our intelligent video surveillance systems, you can see in real-time all the activities that led to the equipment’s failure. This way, you can identify the sequence of events at fault and solve the issue quickly.

3. Streamline Operations and Prevent Losses

Real-time monitoring can help you identify staff effectiveness, as well as faulty processes that may lead to losses. The traditional way of identifying process faults (through human inspectors monitoring the lines) can’t be as comprehensive as video surveillance. Moreover, the latter comes with a hard-to-beat advantage: the bird’s-eye-view perspective, something that is impossible to achieve through human eyes alone.

This is why 93% of companies that use video systems for cross-functional benefits report a positive impact on operations.

4. Improve New Employee Training

Whether it’s health and safety or line production training, it’s often hard to know which aspects to emphasize for new employees. Video monitoring can help point out common knowledge gaps in your new employees.

This way, you can prevent accidents, improve efficiency, limit loss, and prevent food contamination. Through video surveillance, you can catch these knowledge gaps and address them better in your initial training—before they turn into serious issues.

5. Improve Health and Safety

The biggest concern of food processing plants, health and safety, can be aided by video monitoring as well. In complex food supply chains, there are far more chances for the food to get contaminated. Each new stage (from slaughtering or harvesting to processing and transportation) has its own risks.

Video surveillance can help you identify the riskiest stages and address each problem before it turns into a major one. Furthermore, if you identify a problem in one of your food supply chains, you don’t need to stop everything to investigate—you can simply limit the problem-prone processes.

Why Work with Opticom for Food Processing Facilities Video Monitoring

At Opticom, we know that the right video monitoring system can make or break your facility. After 40 years in industrial video technology, we have the expertise to bring you the most suitable technologies for your facility.

Our food processing cameras meet the Stainless AISI 316 standard, so you can always be compliant and enjoy your investment for longer.

Need cameras for food processing facilities? Our CC02 camera was designed specifically for environments with moisture, high vibrations, and extreme temperatures. Our CC06 range is corrosion and bacteria-resistant, which makes it ideal for food processing environments.

Not sure which cameras are right for your facility? Get in touch, we’d love to work with you.