The supply chain disruption that started in 2020 and isn’t fully repaired yet brought new challenges to industrial manufacturers. They were no longer only competing on price and shipping speed—they were also competing on manufacturing speed, productivity, and efficiency.

If you work in an industrial setting, you surely know what we’re talking about; maximizing efficiency has always been a priority in this space, but never more so than now. When the world demands your products and is even willing to pay a premium for them, you have to do everything in your power to satisfy that demand and deliver to as many clients as possible as fast as possible.

Cutting corners to meet demand is the fastest way to put yourself out of business. Enhancing productivity and efficiency, on the other hand, are the best ways to make sure you’ll be in business for years to come.

Enter industrial video monitoring solutions—the easiest way to figure out which processes can be improved and how.

How Industrial Video Monitoring Optimizes Efficiency and Productivity

Unlike other productivity and efficiency enhancement solutions, video monitoring has a huge advantage: it doesn’t disrupt your business.

If you hired an outside expert to monitor your processes on-site, for instance, their presence will disrupt production lines. More importantly, your workers would be aware of their presence and they wouldn’t act as they usually do.

Installing an industrial video monitoring solution is fast and affordable and doesn’t need to disrupt production. Afterward, it’s business as usual. You can even hire an expert to assess everything remotely by watching the recordings or through the live feed.

Moreover, industrial video monitoring can help you:

Find Areas for Improvement

By monitoring your operations remotely, you can spot areas where your workers aren’t as efficient or as productive as they could be. More often than not, this problem stems from their initial training.

Once you’ve identified the issue, you can retrain workers and add specific training items for your new employees. Very quickly, you can boost efficiency and productivity by identifying and making small changes.

Identify Bottlenecks

Is there an unnecessary break in your process? A machine that’s not fully leveraged? Perhaps there’s too much space between two pieces of equipment and moving the products between them takes too long?

Video monitoring can help you identify bottlenecks like these much better than on-site monitoring can. You can uncover many opportunities by simply watching how a full day of work unfolds.

Complete Faster Quality Checks

Not everything that comes out of your production line is perfect. Glitches happen and it’s important to prevent imperfect products from ending up on the shelves.

Manually checking each product is time-consuming and can slow down your production line considerably. Plus, it’s prone to error.

Video monitoring can help you check the quality of your products remotely. You can zoom in or out whenever you need and even contact the on-site workers so they perform manual checks only on a couple of products, the ones that have been flagged by the remote inspector.

Improve Worker Safety and Security

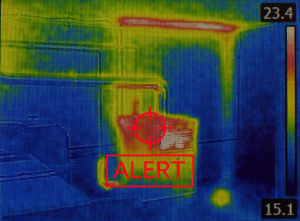

Every plant manager knows that worker safety and security come first. However, when you are on-site, it can be hard to see a helmet that’s not worn properly, a conveyor belt that’s about to snap, or a pipe that’s about to burst.

The bird’s-eye-view of video monitoring can save the lives of your workers and prevent disruption to your business.

How to Optimize Efficiency and Productivity Using Industrial Video Monitoring

Now that you see the benefits of using industrial video monitoring to optimize processes, here are a few ways you can take that knowledge and apply it.

- Workflow Analysis: Video cameras strategically placed along the production line or within the facility provide a comprehensive view of how materials, components, and products move through different stages of the process. By reviewing video footage, managers and engineers can identify areas where materials may be piling up, where workers might be waiting for equipment, or where congestion occurs. This analysis can highlight workflow bottlenecks that need attention.

- Cycle Time Measurement: Video monitoring can be used to measure cycle times for various tasks and processes. This data helps in understanding the time it takes to complete specific operations. If certain tasks consistently take longer than expected, adjustments can be made to streamline those processes.

- Resource Allocation: Video feeds can reveal how workers and equipment are being utilized. For example, you can observe whether machines are idle or underutilized during specific shifts or whether workers are spending excessive time on non-productive activities. This information allows for more efficient allocation of labor and equipment resources.

- Material Handling Efficiency: Video monitoring can track the movement of materials and components throughout the facility. By analyzing how materials are transported, stored, and used, you can identify opportunities to optimize material handling processes. This might involve rearranging storage areas, improving conveyance systems, or automating certain tasks.

- Error Detection: Video cameras can capture instances of errors, defects, or quality issues as they occur in real-time. This allows for immediate corrective actions to be taken. Analyzing these incidents over time can lead to process improvements and quality control measures that prevent such errors from recurring.

- Production Scheduling: Video monitoring combined with data analytics can help refine production scheduling. By tracking actual production rates and identifying factors that affect them, such as machine downtime or workforce availability, managers can adjust production schedules to better match demand and minimize idle time.

- Continuous Improvement: Video monitoring provides a continuous source of data for process improvement initiatives. Regular reviews of video footage can help identify trends and patterns that may not be apparent through intermittent data collection methods. This continuous feedback loop supports a culture of continuous improvement within the organization.

- Safety and Compliance: Process optimization through video monitoring also includes ensuring that safety protocols and regulatory compliance are maintained. Video footage can be reviewed to confirm that workers are following safety procedures and that environmental regulations are being adhered to, minimizing disruptions due to compliance issues.

- Energy Efficiency: In some industrial settings, video monitoring can extend to tracking energy consumption. By analyzing video footage alongside energy data, it’s possible to identify areas where energy is being used inefficiently and take steps to reduce consumption.

- Predictive Maintenance: Video data can be used to monitor equipment conditions and detect signs of wear and tear, which can be early indicators of potential breakdowns. This allows for predictive maintenance strategies, ensuring that equipment is serviced or repaired before it fails, reducing downtime and optimizing production.

Video monitoring is a valuable tool for process optimization in industrial environments as it provides real-time visibility, data-driven insights, and a comprehensive view of operations. By leveraging the information gathered from video feeds, organizations can make informed decisions to enhance workflow efficiency, reduce waste, and ultimately improve overall productivity and competitiveness.

Choosing the Right Industrial Video Monitoring System

Industrial video monitoring comes with many benefits across many areas. However, you can’t reap those benefits with just any video monitoring system.

First and foremost, your system has to withstand the environment of your plant, which takes off-the-shelf cameras off the list. You will most likely need cameras that can withstand humidity, high vibrations, dust, temperature changes, and more.

You can read more about how to choose the right industrial video monitoring system here. Need an expert in your corner? We’ve spent 50+ years helping plant managers choose the right systems for the right applications. Talk to one of our consultants—it’s 100% free.