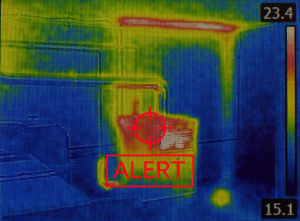

Video monitoring is a valuable tool for sawmill safety. It can help identify hazards before they become serious problems, and it can also be used to investigate accidents after they occur.

By now, most sawmills have some form of video monitoring in place to watch for potential problems. It may be through a live feed that someone is watching in real-time, via recorded footage that is reviewed later, or a combination of live and recorded video.

For all these reasons, sawmills should make sure that their video monitoring systems are up to date, working properly, and can withstand the harsh sawmill environment.

Install Video Equipment Built for Sawmills

Sawmills are unique environments, with a lot of noise, vibration, and debris. Off-the-shelf cameras from big box stores, or even those made for other industrial applications, don’t cut it in the sawmill. When sawmill video monitoring systems use standard equipment, it isn’t reliable and has to be replaced frequently.

At Opticom, we have video monitoring equipment designed specifically for the sawmill environment. They have been tested and are proven to perform and outlast other systems.

Opticom cameras optimized for sawmills includes:

- CC02 Industrial Analog Camera

- CC02-TVI Industrial HDTVI Camera

- CC03 Explosion Proof Camera

- CC04-IP2MV Industrial IP Network Camera

In addition to an industrial, vibration-resistant camera, sawmills should use mounts that are designs for high-vibration environments. The Opticom VM-1 Vibration/Shock Mount further protects the rugged CC02 camera from vibration. Most of our customers have to replace the vibration mount long before they have to replace the cameras—and often years after initial install.

Improve Safety With Remote Video Monitoring

We all know how dangerous the sawmill floor is. Remote video monitoring lets operators keep an eye on the line without being in dangerous proximity to logs and debris. By installing rugged video cameras and routing footage to a central monitoring area, operators can observe from a safe distance. They’re close enough to troubleshoot issues but far enough away to keep safety a top priority.

Just like the cameras, the monitors in a sawmill’s video system need to be able to withstand the hard environment. We offer sawmill CCTV monitors in a variety of sizes, definitions, and connectivity options. We also offer the MVM-LCD-1 Vibration Mount that helps extend the life of video monitors inside sawmills.

With safety being a high priority, a video system with remote monitoring capabilities is a surefire way to keep operators far from danger.

Store Video Footage to Troubleshoot Issues

In addition to remote monitoring, sawmills can record and store video footage. By watching footage of the sawmill process, operators can identify potential problems and make corrections before they cause damage or downtime. In addition, video footage can be used to track production rates and identify areas where improvements can be made. By constantly monitoring the sawmill process, operators can ensure that the mill is running smoothly and efficiently.

We offer sawmill video recorders from 4 to 64 channels and with recording via DVR, NVR, and/or POE.

At Opticom, we’re more than an equipment vendor—we’re a partner. We’ll help you evaluate your options for sawmill video monitoring, networking, and storage to set you up with a complete system that meets your needs. For a no-obligation review of your sawmill video needs, contact us.

There’s a better way to monitor sawmill operations with the right video systems.