There are few environments as challenging as sawmills for video monitoring. In a sawmill, precision has to meet productivity and a video monitoring system has to support both of these.

However, amid the cacophony of heavy machinery and the inherent challenges of rugged environments, implementing a video monitoring system is no small feat. Sawmills present unique challenges, from extreme working conditions and dust-filled air to inaccessible areas and dynamic production processes.

So can you create a video monitoring system that supports seamless productivity in sawmills? Our 50+ years of experience in this exact area say “yes.” We love a good challenge, which is why we’re the preferred video monitoring solutions provider for sawmills.

We work with sawmill electrical managers nearly every day, so we know their challenges inside and out. These are a few of the issues you will commonly encounter when building a video monitoring system for sawmills as well as how to overcome those challenges.

The Challenges of Sawmill Video Monitoring

In sawmills, video monitoring has to adapt to the environment, not the other way around. You build products designed to withstand the environment—and so do we. Equally important, our video monitoring products make monitoring a breeze, not another challenging work task.

1. Mounting Cameras on Heavy, High-vibration Machinery

Sawmill equipment has incredibly high levels of vibration and noise, both of which are very harmful to the delicate intricacies of video cameras. Before working with Opticom, most sawmill electrical managers had to use makeshift solutions, like mounting the cameras on rafters, or had to replace their cameras up to every few weeks!

Mounting cameras in the rafters or in other less-than-ideal areas isn’t just cumbersome; it also reduces the quality of your video feed. When you’re limited by where you can place the cameras because they’re fragile, the cameras can’t capture the video angles or quality you want and need.

Opticom’s rugged industrial cameras, like the CC02 and CC04, for instance, are specifically built to withstand high levels of vibration, even those of heavy machinery like that in a sawmill. You can mount Opticom cameras directly on your sawmill equipment—like on a log debarker or chipper and inside cantors—to get all of the angles and views you need. Using a vibration mount allows flexibility for placement and protects the camera even further from the hazards of sawmills.

Cameras mounted on equipment don’t interfere with the machine in any way, and their feed can be easily followed by a remote operator with the best view of the mill’s operations.

2. Commercial Cameras Need to Be Replaced Often

Off-the-shelf cameras may be very cheap, but they are also quick to break or break down in a sawmill. Given the amount of dust, debris, and vibrations in a sawmill, some cameras will last for less than a week. (Really…we’ve had customers who, before Opticom, were replacing cameras almost weekly.)

If you install off-the-shelf cameras, you will end up paying a lot more to replace them every week or every month. You have to account for both the costs of the cameras as well as the cost of labor to replace them and, of course, line downtime while the cameras are offline.

Opticom cameras are ruggedized and specifically created for the harsh environment in a sawmill. They last for years, not months, lowering your total cost of ownership almost immediately.

3. Cameras Get Hit By Logs

Sawmills aren’t for the faint of heart. Debris, logs, and boards are moving quickly around the mill. Cameras, when placed properly, are right in the middle of the action. Therefore, there’s always the chance of them getting hit with debris or even a log or board.

In fact, it has happened—more than once.

When we say Opticom cameras can withstand nearly anything, we mean it literally. The video below was sent to us by a client and it shows exactly what happens to a camera that gets hit by a log.

As you can see, nothing happened to the camera, it’s still in perfect working condition. The only thing that needed to be replaced was the vibration mount.

That’s not the only time. We’ve also run Opticom cameras over with a truck, and one was speared by a board where, again, the camera still works and just the vibration mount needed to be replaced. Here’s a photo of the CC04 camera after a direct hit:

Things happen in sawmills. This is why you need rugged, industrial Opticom cameras that can take whatever is thrown at them…literally.

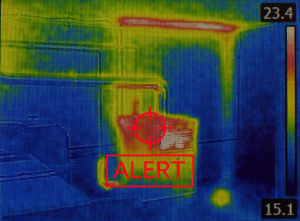

4. Remote Video Monitoring in Sawmills

Around heavy machinery, accidents and incidents are common. You want to reduce these risks to a minimum, the last thing you want to do is add more personnel near them.

This is why sawmills need a sturdy remote video monitoring solution.

With Opticom technology, all you need is an operator booth at a safe distance from logs and debris. They can monitor the activity inside the mill on their networked video feeds and intervene when they spot a potentially faulty piece of machinery or an impending incident.

Remote monitoring doesn’t stop at the walls of the mill—operators and managers can also view video feeds on a mobile app to see operations in real time. Just download an app, connect it with your mill’s video feeds, and securely view operations on the go.

5. Hard to Get Close Views of Operations

While it’s fairly easy to monitor loading operations and other tasks that are usually performed outside the “heart” of a sawmill, getting views from the line is a bit trickier—unless you have Opticom cameras.

As mentioned previously, off-the-shelf commercial cameras just can’t be mounted on or sometimes near equipment. Electrical managers do what they can to get views of the line—mount in rafters, mount far away and zoom in with a low-quality output, and more—but they don’t have to.

Opticom cameras can be mounted in the harshest, most rugged of spaces. This way, you can:

- Detect potential machinery issues as early as possible

- Avoid accidents and various incidents

- Avoid costly downtime

- Keep workers safe

You get a full, real-time view of your sawmill equipment so you can always operate it safely and seamlessly. Check out this setup of one of our sawmill customers. It’s safe, secure, and effective.

Choosing the Right Sawmill Video Monitoring System

While these are some of the most common challenges we have seen with sawmill video monitoring, we know that every sawmill is unique and has unique needs. This is why Opticom representatives work to understand the specific needs of your sawmill and recommend cameras, monitors, networking, camera placement, and more specifically for your mill.

Want to make sure that you get the most out of your sawmill video monitoring system? Talk to our consultants—we’ll recommend a solution that overcomes your challenges.